Dicing and Cubing Machine in Agra

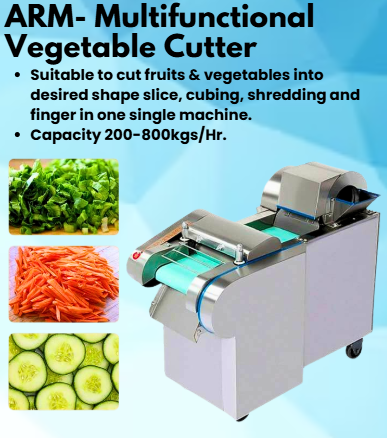

Agra’s sweet and snack manufacturers are investing in automation for consistency. Famous for confectionery and traditional Indian food sectors. Explore Dicing and Cubing Machine — cut fruits and vegetables into uniform cubes with precision. in Agra.

Why Choose Dicing and Cubing Machine in Agra?

Cut fruits and vegetables into uniform cubes with precision.

| Specification | Details |

|---|---|

| Power | 1200W |

| Capacity | 80 kg/hr |

| Material | Stainless Steel |

| Suitable for | Potato, Carrot, Cucumber, etc. |

| Blade Types | Cubing, Dicing |

| Usage/Application | Commercial |

| Design | Compact |

| Speed | 1500 RPM |

About Dicing and Cubing Machine in Agra

The Dicing and Cubing Machine is a highly efficient and versatile food processing solution designed to cut fruits and vegetables into uniform cubes and diced shapes with accuracy, speed, and consistency. In commercial kitchens and industrial food processing plants, uniform cutting is not just about appearance—it directly affects cooking time, packaging quality, freezing efficiency, and overall product standardization. Whether you are producing ready-to-cook vegetable packs, frozen vegetable mixes, salad ingredients, or bulk-cut vegetables for hotels and catering services, this machine helps you achieve professional-grade results in less time and with reduced labor dependency. In many food industries, consistency is a major requirement. When vegetables are cut unevenly, some pieces cook faster while others remain undercooked, creating inconsistent taste and texture. Uneven cutting also causes problems in packaging because different sizes affect weight distribution and product presentation. The Dicing and Cubing Machine solves this issue by producing uniform cuts every time, ensuring your final product looks premium, cooks evenly, and meets quality expectations. This machine is widely used for cutting vegetables such as potato, carrot, cucumber, and other similar raw materials. Potatoes are one of the most common ingredients for dicing and cubing because they are used in products like French fries, potato cubes for frozen foods, soups, and snacks. Carrots are frequently diced for mixed vegetables, frozen packs, soup bases, and ready-to-cook meal kits. Cucumbers are commonly used in salad packs, hotel kitchens, and food service supply chains. With the ability to handle multiple raw materials, this machine provides flexibility for businesses working with different vegetables based on market demand. The Dicing and Cubing Machine comes with blade types designed specifically for cubing and dicing. Blade performance is critical in cutting machines because it determines the sharpness, accuracy, and smoothness of cuts. High-quality blades ensure clean cutting without crushing or damaging the vegetables. Clean cuts help preserve freshness, reduce moisture loss, and improve shelf life in packaged products. This is especially important for businesses supplying pre-cut vegetables to supermarkets, hotels, and food delivery kitchens. Powered by a 1200W motor, the machine delivers reliable cutting performance for commercial operations. Motor strength plays a major role in maintaining consistent speed and cutting efficiency. When cutting harder vegetables like potatoes and carrots, the motor must maintain stable torque to prevent jamming or uneven cutting. A powerful motor ensures smooth operation, reduces downtime, and supports continuous working conditions. The machine offers a capacity of 80 kg/hr, which makes it ideal for small-to-medium scale food processing units, commercial kitchens, restaurants, and catering businesses. Many food service operations require consistent supply of diced vegetables throughout the day. With an 80 kg/hr capacity, this machine can meet daily cutting requirements efficiently while saving time and reducing labor workload. The machine is made from stainless steel, which ensures durability and hygiene. Stainless steel is the preferred material in food processing because it resists corrosion, is easy to clean, and does not react with food products. Since vegetables contain moisture and natural acids, using stainless steel helps maintain long-term performance and prevents contamination. Food-grade construction also supports better hygiene compliance, which is essential in commercial processing environments. One of the key benefits of a dicing and cubing machine is reduced manual labor. Manual cutting requires skilled workers, takes a lot of time, and often results in inconsistent sizes. It also increases wastage because uneven cutting leads to more trimming and rejects. By using this machine, businesses can reduce labor dependency, improve cutting accuracy, and increase overall productivity. It also allows workers to focus on other important processing tasks such as sorting, packing, and quality checking. The Dicing and Cubing Machine is also useful for food businesses producing soups, sauces, and ready meals. Uniform vegetable cubes are essential in soup manufacturing because they ensure consistent cooking and improve the final product appearance. Many ready-meal manufacturers use diced vegetables in curries, gravies, pasta sauces, and frozen meal trays. Having a reliable dicing machine helps maintain standardization across batches, which is critical for branded food production. The compact design makes the machine easy to install in different workspaces. Many commercial kitchens and processing units face space limitations. A compact cutting machine provides high performance without requiring large floor area. It can be placed in vegetable preparation zones and integrated with washing machines, peeling machines, and packing tables. This machine operates at a speed of 1500 RPM, which supports fast cutting cycles and smooth output. Speed ensures higher productivity and helps meet bulk cutting demands during peak hours. Consistent speed also ensures that the cut size remains uniform throughout operation. From a business perspective, investing in a Dicing and Cubing Machine improves output quality, reduces labor costs, and increases production efficiency. It supports faster order fulfillment for catering businesses, improves packaging consistency for retail supply, and enhances product presentation for ready-to-cook markets. It also reduces wastage by ensuring accurate cuts with minimal trimming loss. Cleaning and maintenance are also important for cutting machines. Regular cleaning after each use prevents vegetable residue buildup and ensures hygienic operation. Stainless steel body construction makes cleaning easier and helps maintain food safety standards. In summary, the Dicing and Cubing Machine is an essential vegetable cutting solution for commercial kitchens and food processing plants. With a 1200W motor, 80 kg/hr capacity, stainless steel construction, cubing and dicing blade options, compact design, and 1500 RPM speed, it delivers uniform cutting results with high efficiency. It is ideal for businesses that require consistent diced and cubed vegetables for salads, soups, frozen foods, and ready-to-cook product manufacturing.

In Agra, famous for confectionery and traditional indian food sectors. benefit from Dicing and Cubing Machine for high productivity and reliability. Areium delivers durable and efficient Dicing and Cubing Machine with service support in Agra.

Looking for more? Check all machines available in Agra or browse full catalog.