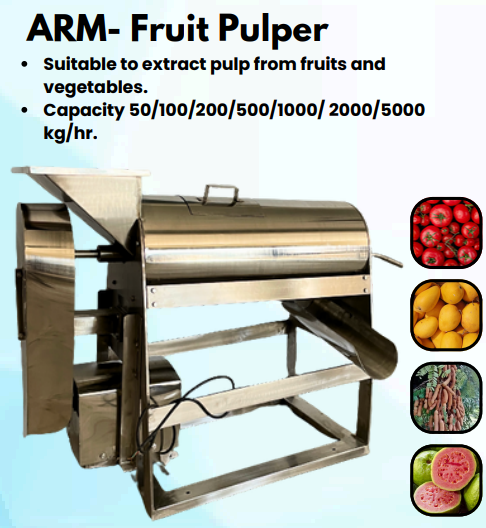

Fruit Pulper in Lucknow

Lucknow’s food manufacturers are modernizing with stainless steel automation systems. Strong in dairy, bakery, and traditional Indian foods. Explore Fruit Pulper — perfect for extracting fruit pulp with minimal waste. in Lucknow.

Why Choose Fruit Pulper in Lucknow?

Perfect for extracting fruit pulp with minimal waste.

| Specification | Details |

|---|---|

| Power | 1200W |

| Capacity | 500 kg/hr |

| Material | Stainless Steel |

| Suitable for | Mango, Guava, Tomato, etc. |

| Pulp Extraction Rate | 80% |

| Usage/Application | Commercial |

| Design | Compact |

| Type | Batch Type |

About Fruit Pulper in Lucknow

A Fruit Pulper is one of the most important machines in modern fruit processing because it transforms fresh fruits into smooth pulp with minimal waste, maximum yield, and consistent output quality. In commercial food production, pulp is the foundation for multiple finished products such as fruit juices, fruit concentrates, purees, jams, nectars, sauces, dessert fillings, and even bakery ingredients. The demand for processed fruit products is increasing rapidly due to changing consumer lifestyles, rising preference for packaged foods, and the need for long shelf-life products that maintain natural taste and nutrition. A high-performance Fruit Pulper helps food businesses meet this demand efficiently. This Fruit Pulper is designed to extract pulp from a wide variety of fruits while separating seeds, peels, and fibrous waste. The main purpose of a pulping machine is to produce a uniform pulp texture, reduce manual handling, and maintain hygiene during processing. Manual pulping is slow, inconsistent, and leads to high losses because a significant amount of pulp remains trapped in fruit skins or gets wasted during handling. With an industrial pulper, the pulp extraction process becomes faster, cleaner, and more profitable. One of the strongest advantages of using a Fruit Pulper in your processing setup is the ability to maintain product consistency. In industries like juice manufacturing or jam production, consistency matters because the texture and thickness of pulp directly affect the final product’s quality. If the pulp contains too many seeds, uneven pieces, or fibrous particles, it can create problems in filling lines, packaging machines, or even customer satisfaction. This machine ensures that the pulp produced is smooth, uniform, and suitable for further processing. The Fruit Pulper is suitable for processing fruits like mango, guava, tomato, and many other pulp-based raw materials. Mango pulping is one of the most common commercial applications because mango pulp is used in juices, milkshakes, ice creams, sweets, bakery products, and export-based packaged goods. Guava pulp is popular for nectar production, beverages, jams, and fruit blends. Tomato pulping is widely used in ketchup plants, sauce plants, puree manufacturing, and paste production lines. Having a pulper that can handle multiple fruits provides flexibility and allows businesses to expand into different product categories depending on market demand and seasonal availability. This pulper comes with a strong pulp extraction rate of around 80%, which is a major benefit for profitability. Higher extraction means more finished product output from the same quantity of raw fruit. In commercial processing, raw material cost is often the biggest expense, so improving yield directly increases profit margins. For example, if you process 1000 kg of mangoes and improve pulp yield by even 5–10%, that can create a significant increase in daily output. Over weeks and months, this difference becomes huge in terms of revenue. The machine is powered by a 1200W motor, which provides enough strength for consistent pulping performance in commercial environments. A reliable motor ensures stable processing without frequent stoppage. In food processing units, machines must operate for long shifts, especially during peak seasons when fruits arrive in bulk. The motor power supports continuous operation and stable output, helping you meet production targets without delays. The Fruit Pulper is made from Stainless Steel, which is critical for hygiene and durability. Food-grade stainless steel prevents contamination, resists corrosion, and supports easy cleaning. This is especially important because fruit pulp is acidic in nature. Fruits like mango, tomato, and citrus can react with low-quality metals, causing corrosion, discoloration, and contamination risks. Stainless steel construction ensures the machine remains safe, clean, and long-lasting even with daily exposure to fruit acids, water, and cleaning chemicals. The pulping process typically involves feeding washed and prepared fruits into the pulper chamber. The machine uses internal rotating mechanisms to crush and separate pulp from unwanted parts such as seeds and peels. The output pulp can then be collected in a tank or pipeline for further processing like pasteurization, blending, concentration, or packaging. In larger fruit processing plants, the pulper is often installed in a complete production line that includes washing systems, sorting conveyors, peeling machines, juice extractors, pasteurizers, and filling machines. Another major advantage of this Fruit Pulper is reduced labor dependency. Manual pulping requires multiple workers, high supervision, and longer processing time. It also increases contamination risk because the fruit is handled repeatedly. Automated pulping improves hygiene by reducing direct contact and ensuring the pulp is processed inside a controlled machine chamber. This is a key requirement for food manufacturing businesses aiming to maintain consistent quality and meet safety standards. The pulper is also highly beneficial for businesses focusing on value-added food processing. Instead of selling fresh fruits at low seasonal prices, farmers, entrepreneurs, and processors can convert fruits into pulp and sell it at a higher value. This reduces post-harvest losses, supports year-round income, and allows seasonal fruits to be preserved in pulp form. Many successful food businesses start with pulp production and later expand into branded juice products, jam production, and export markets. For jam and preserve manufacturing, pulp quality is extremely important. A good pulper ensures smooth pulp that blends well with sugar, pectin, and flavors. For juice manufacturing, the pulp must be clean and consistent so that it can be filtered, blended, or homogenized properly. For ketchup and tomato sauce production, pulping is the first major step that decides the thickness and quality of the final product. Cleaning and maintenance are also easier with stainless steel machines. Regular cleaning after each shift helps prevent pulp residue buildup, improves hygiene, and extends machine life. With proper maintenance, the Fruit Pulper can provide long-term performance and stable output for commercial processing. In summary, the Fruit Pulper is a powerful, hygienic, and efficient machine designed for commercial pulp extraction. With 1200W power, 500 kg/hr capacity, stainless steel construction, and an 80% pulp extraction rate, it supports smooth pulp production for juices, jams, sauces, and multiple food applications. For businesses looking to scale fruit processing, improve yield, and maintain product consistency, this Fruit Pulper is a must-have machine for a modern food processing setup.

In Lucknow, strong in dairy, bakery, and traditional indian foods. benefit from Fruit Pulper for high productivity and reliability. Areium delivers durable and efficient Fruit Pulper with service support in Lucknow.

Looking for more? Check all machines available in Lucknow or browse full catalog.